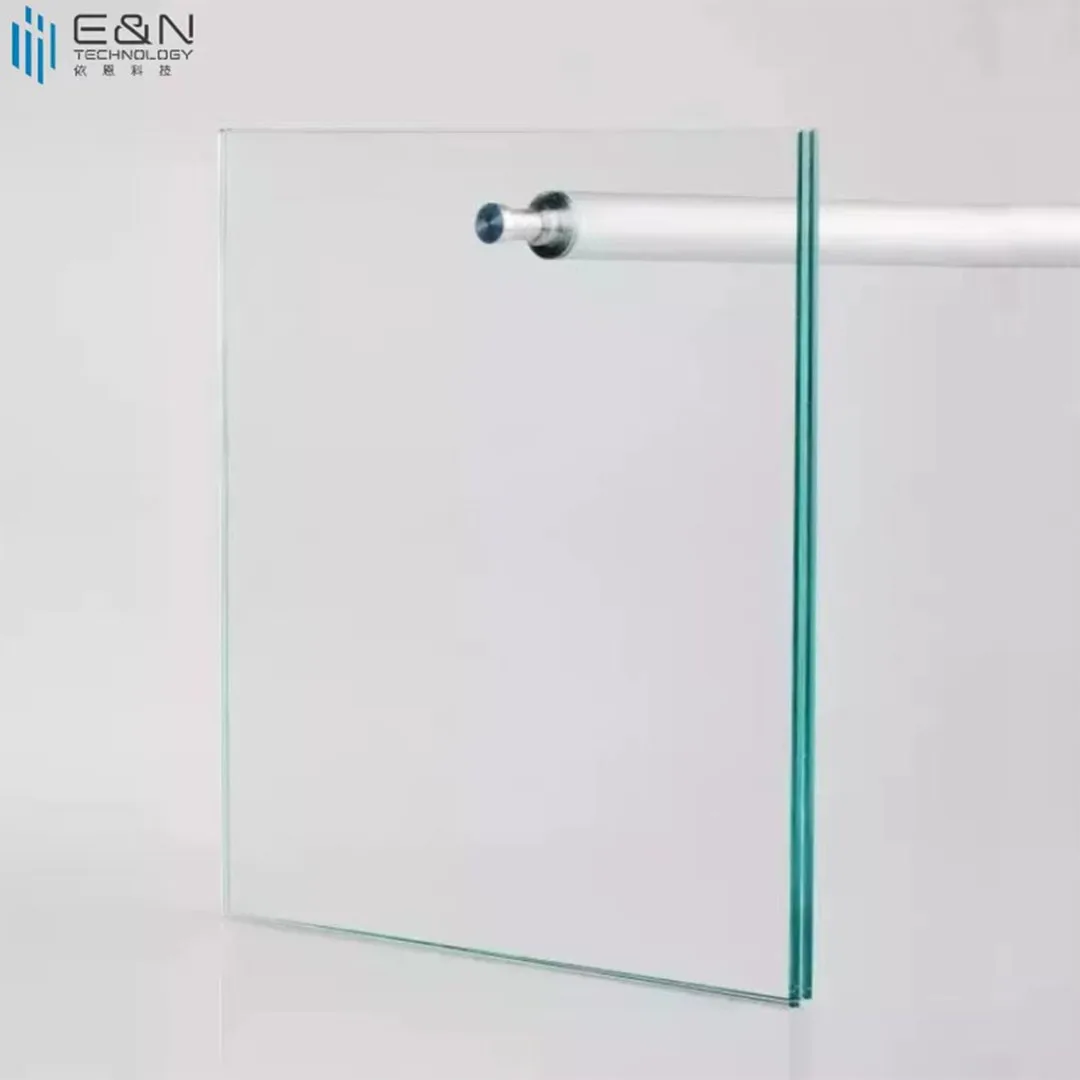

With the development of the glass industry, more and more construction and decoration projects tend to use laminated glass, which is safe and explosion-proof, sound insulation and noise reduction. To this end, E&N developed the VE-AT.

|

VE38AT:

|

|

|

VE76AT:

|

|

|

VE-AT:

|

|

1.High fluidity

2.High transparency, it is an ideal material for laminated glass of architectural decoration engineering

3.Excellent adhesion, low water absorption, bare edge installation will not cause delamination

4.Excellent outdoor weather resistance, high UV blocking rate

5.Easy to operate and process

Laminated glass for outdoor architectural decoration engineering that requires transparency, such as ceiling glass.

|

Test item |

Test method |

VE-AT |

VE-HT |

|

Transmittance |

ISO527-3 |

>90.6% |

>90.4% |

|

Haze |

E&N Laboratory |

<0.29% |

<0.25% |

|

UV blocked rate |

280-380nm |

>99% |

>99% |

|

Tensile strength |

ISO527-3 |

>20MPa |

>21MPa |

|

Adhesion with glass |

ISO-8510 |

>77N/cm |

>95N/cm |

|

Elongation at break |

ISO527-3 |

≥800% |

≥800% |

|

Young's modulus |

E&N Laboratory |

4.4 |

6.0 |

|

Cross-linking rate |

E&N Laboratory |

>85% |

>85% |

|

Water absorption |

ASTMAD570 |

≤0.1% |

≤0.1% |

|

High temperature test 4hrs 100℃ |

EN 14449/EN1SO12543 |

No visible change |

|

|

Humidity resistance 85℃ 85%RH 1000hrs |

ENISO12543 |

Haze appeared just 2.5cm from the edge without bubbles or delamination |

|

|

UV radiation test UVA340 60℃ 65%RH 2000hrs |

EN14449/EN572 |

Yellowing index:Δ<1 |

|

|

Pendulum test(hight:1200mm) |

EN14449/EN 12600 |

Qualified |

|

|

Ball impact peeling resistance(hight:4m) |

GB-15763.3-2009 |

Qualified |

|

Note:the information and relevant data listed in this article are established in the laboratory of the company's technical department,and their contents are correct based on the truth.However,we will not make any statement or guarantee on the integrity or accuracy of the listed information and data.We provide the content of this article on the condition that it is for the user's reference only,and before using it,decide whether the information and data are suitable for their own purpose of use.In no event shall we be liable or liable for damages of any nature whatsoever arising out of the use of or reliance on the content of this document or the products mentioned herein.

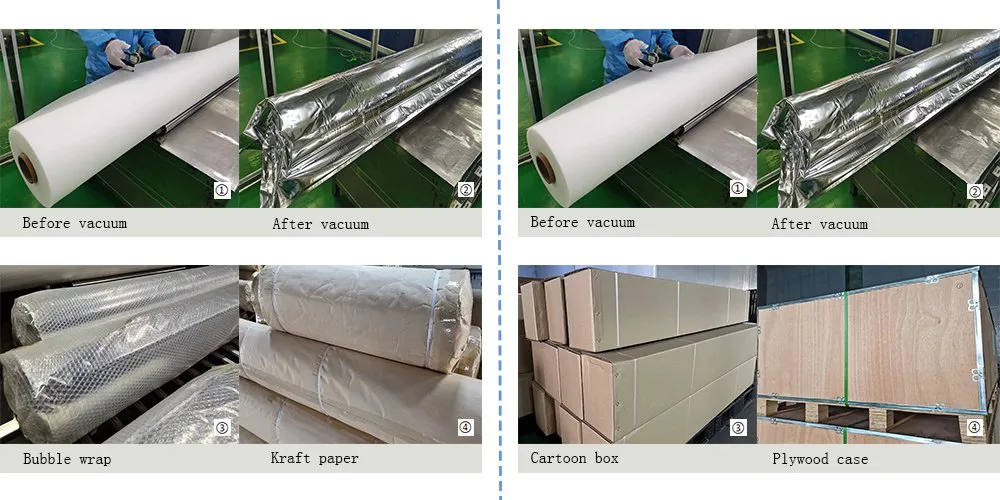

1.Without plywood case: tinfoil vacuum + bubble wrap + composite kraft paper

2.With plywood case: tinfoil vacuum + carton box + plywood case

Shelf Life of Product:

1 year

1. Clean and fully dry the glass, there should be no particle dust or oil on the glass surface, EVA film and other intermediate materials are spare.

2. After opening the furnace, cool down for 3~5 minutes, until the vacuum value reaches -0.095MPa, close the furnace door and officially heat.

|

First step:60℃—20mins |

|||||

|

Second step:125℃ |

Film thickness |

||||

|

0.38mm |

0.76mm |

1.14mm |

1.52mm |

||

|

Glass Thickness |

4+4mm |

55mins |

60mins |

65mins |

70mins |

|

5+5mm |

60mins |

65mins |

70mins |

75mins |

|

|

6+6mm |

65mins |

70mins |

75mins |

80mins |

|

|

8+8mm |

75mins |

80mins |

85mins |

90mins |

|

|

10+10mm |

85mins |

90mins |

95mins |

100mins |

|

|

Full Vacuum Retention:-0.095MPa |

Temperature Out of Furnace:<50℃ |

||||

The above-mentioned temperature refers to the glass surface temperature.The above parameter settings are for reference only, and the specific parameters should be adjusted according to the laminating equipment, temperature, humidity, glass thickness and intermediate layer material.

1.What is the difference between VE-AT and VE-HT?

VE-AT is a low flow film and has better light transmission, while VE-HT is a high flow film and has better hardness. There are some differences in the application fields of the two different types of films.

2.If there is too much film overflow, how to solve it?

Before lamination, please use green tape for edge sealing,and put the wood stick around the edge of glass.Please reduce vacuum value for second stage if necessary.

3.Can I control the overflow by reduce the vacuum or reduce the temperature?

I don’t suggest reduce the vacuum and temperature as the first step to avoid this problem,because lower vacuum and temperature will effect it crosslink and transparency,and it is possible to occur bubbles.

4.What is the data value of the high flow melted index and low flow melted index?

The high flow melted index can reach 15, but the low flow melted index is only 5-7.

5.What is the MOQ?

Generally, there is no MOQ for processed glass, but if you want to received best price, the more quantity, the better price.