Online Message

Your satisfaction is our biggest motivation.Welcome to leave your valuable comments!

Contact Us

E&N provides customers with a one-stop solution for glass lamination processing. From equipment , materials and accessories to processing technical support, we fully support customers to produce high-quality laminated glass and solve customers' worries.

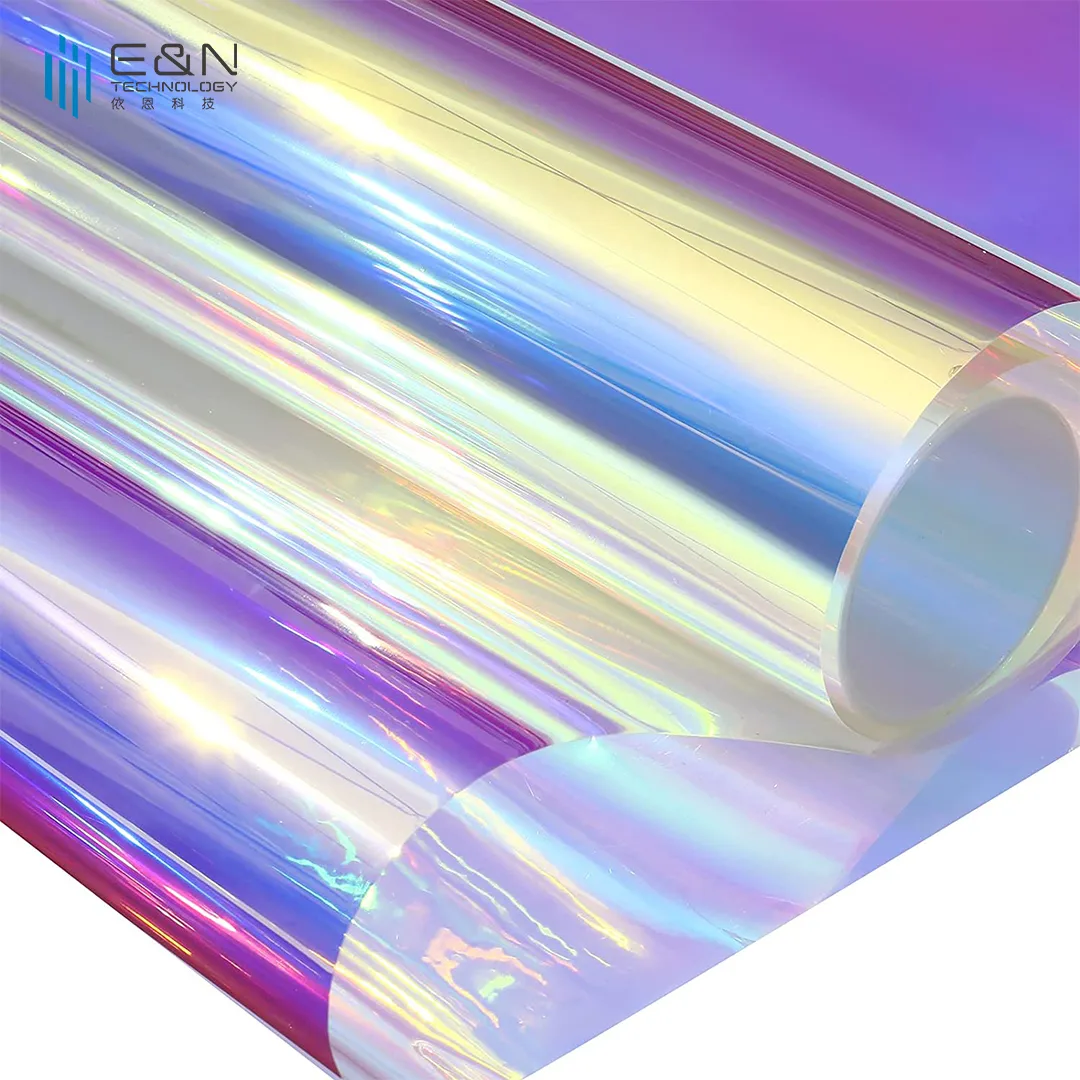

Dichroic film is a plastic composite film that melts and extrudes two or more resins with different refractive indices and stacks more than 100 layers at intervals. Each layer is only a few hundred nanometers thick.

Learn More

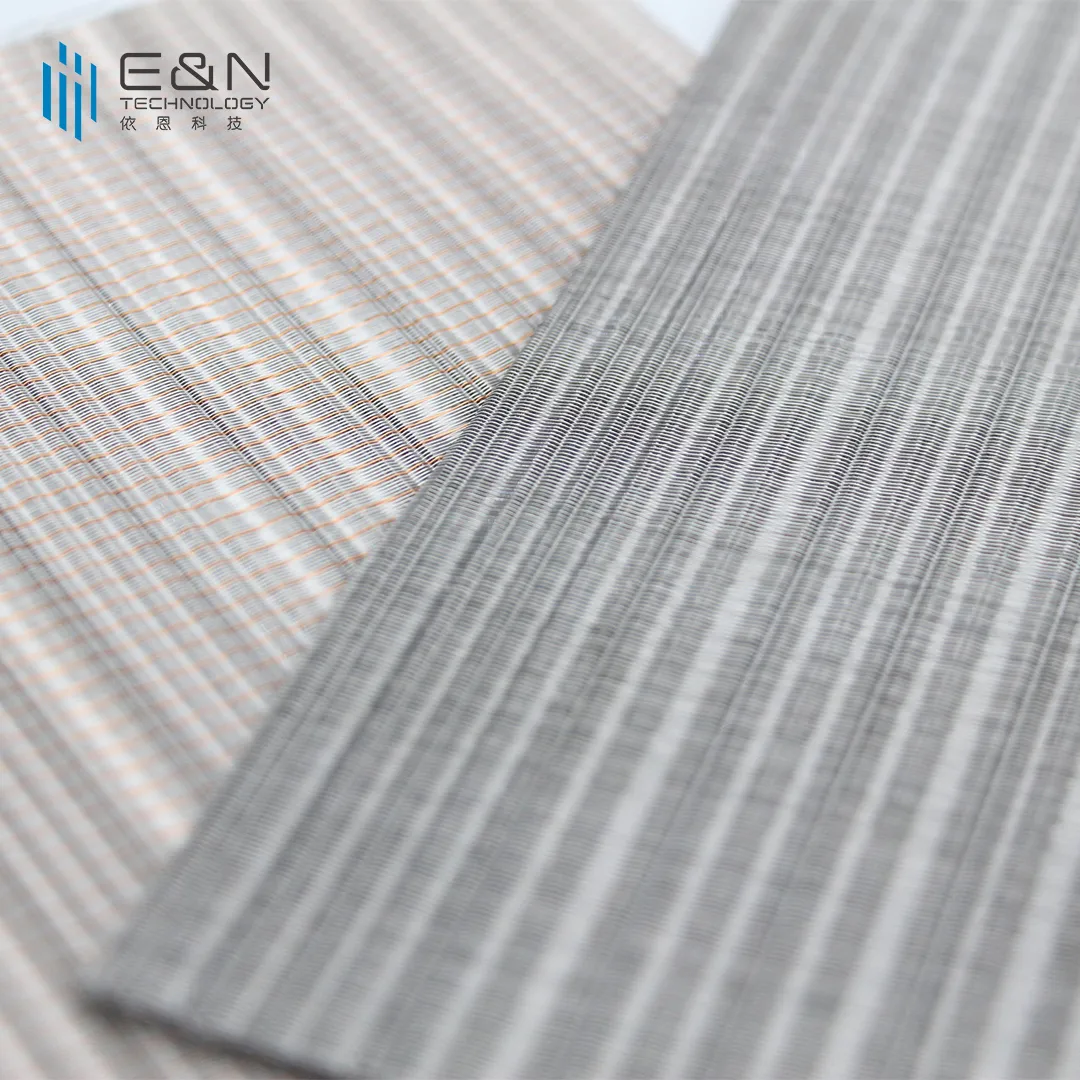

EN-JS metal mesh is a copper mesh made of copper, which is an auxiliary material for wired glass. EN-JS is mainly used in the field of indoor decoration, which not only makes the indoor beautiful, but also makes the glass safer.

Learn More

LYX-600 formula used German technology. It is a single component, neutral curing high performance silicone sealant and especially designed for adhesion and sealing of EVA laminated glass industry.The product has good adhesion with EVA, metal, glass and other materials. During the curing process, there is no reaction between small molecules and EVA. LYX-600 has extremely high water resistance, high and low temperature resistance, aging resistance, UV resistance, especially in closed, humid and non-ventilated extreme environment and reflects the excellent compatibility of EVA.

Learn More

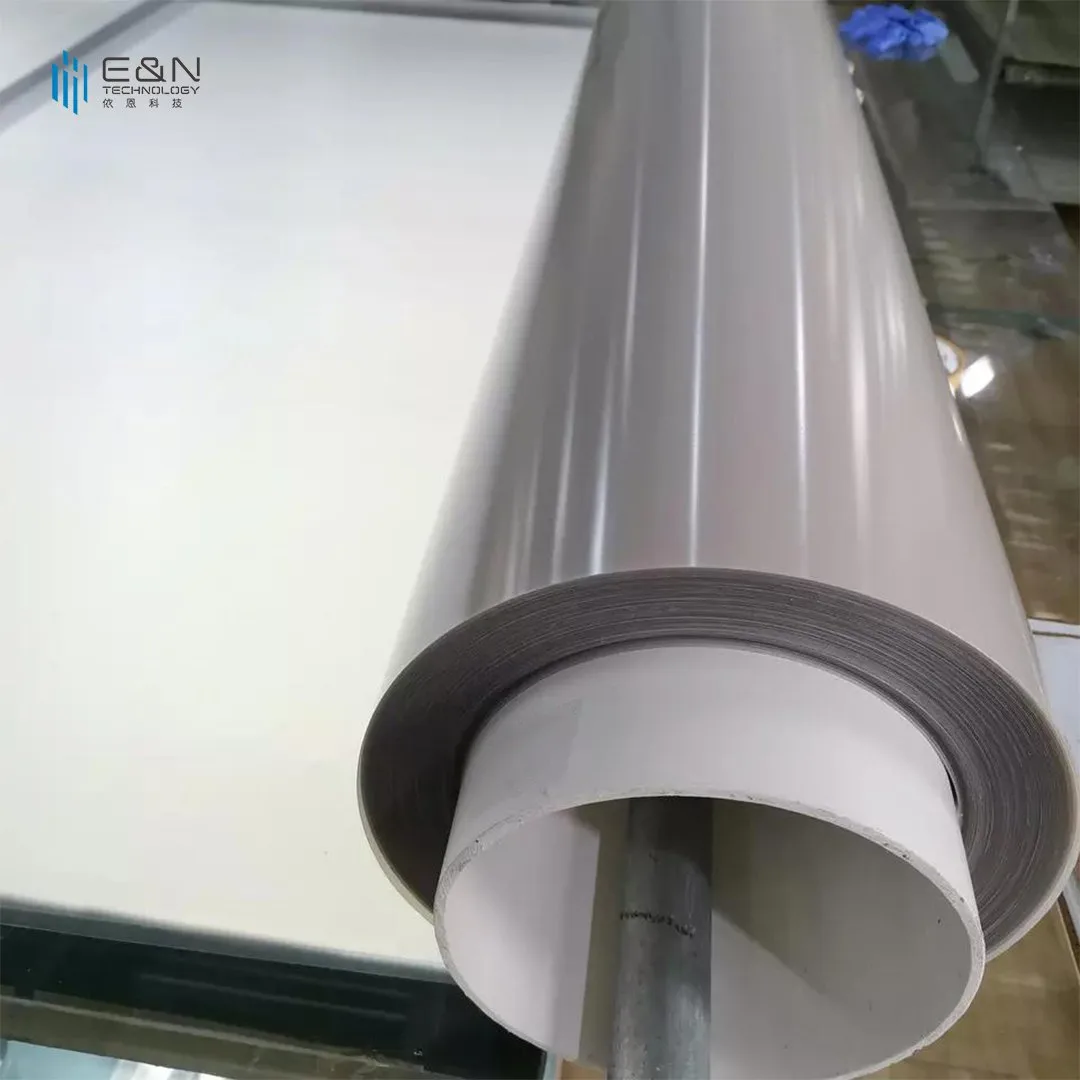

The principle of the laminating furnace is to use new EVA film to bond two or more pieces of glass together through high-temperature extrusion. The laminated glass has many advantages such as high strength, waterproof, safety and explosion-proof

Learn More

The wire material can be laminated into 2 pieces of glass through EVA film for decorative glass or decorative glass doors and windows.With colorfulm and multi choises for your interior design.

Learn More

The PDLC film is made of polymer dispersed liquid crystal and flexible transparent electrodes through a special process. When the power is off, the visible light is scattered when it passes through and becomes opaque and foggy. When the power is on, the visible light can penetrate smoothly and make it appear transparent effect.

Learn More

Autoclave is safety laminated glass processing equipment. Our MG and EG models require autoclave processing.

Learn More

The vacuum bag is the core component of the glass vacuum lamination furnace. It consists of two upper and lower silicone plates and special-shaped silicone seals. The silicone plate is the key component of the whole lamination furnace. Its quality directly affects the quality of glass product.

Learn More

PET high temperature green tape is used to fix the four sides and four points of the glass in the lamination process to prevent the glass from shifting.

Learn More