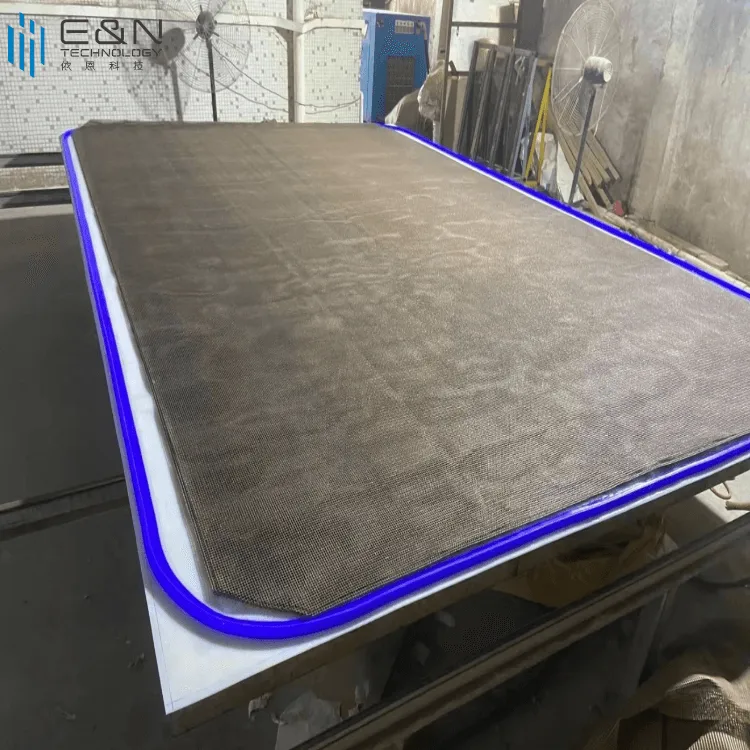

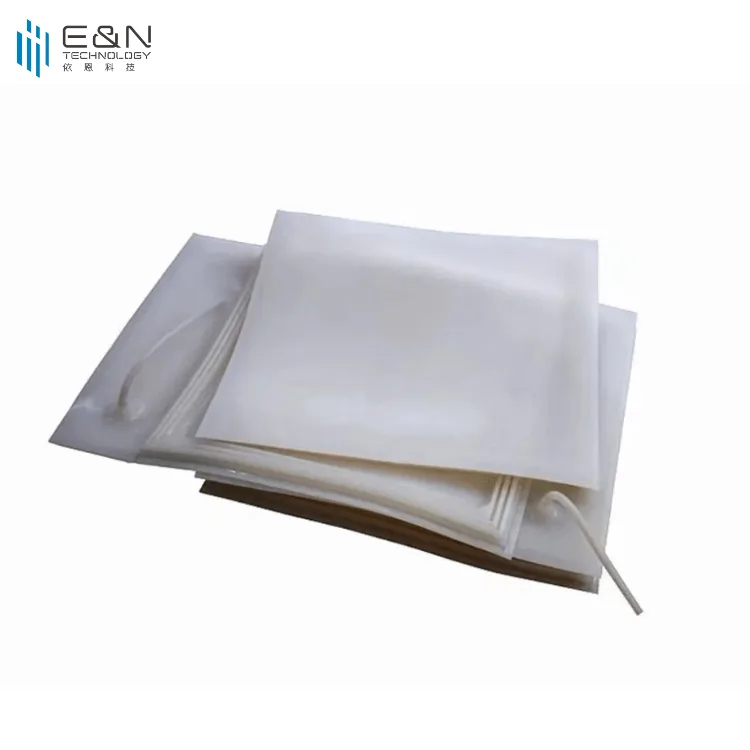

The vacuum bag is the core component of the glass vacuum lamination furnace. It consists of two upper and lower silicone plates and special-shaped silicone seals. The silicone plate is the key component of the whole lamination furnace. Its quality directly affects the quality of glass product.

Vacuum bag of glass lamination furnace

The special silica gel plate for the glass industry is the key component of our company specially designed for the glass vacuum lamination furnace according to the market demand.

The quality of the silicone bag directly affects the quality of the laminated glass. The silicone plates produced by our company are divided into ordinary silicone plates and high tear resistant silicone bags according to different requirements of users. The non splicing of laminated glass vacuum bag is the biggest advantage of our company, which makes the thickness of the whole silicone rubber plate more uniform, better air tightness, higher tear strength and longer service life, ensuring the quality of glass products.

|

Tear strength Mpa |

12 |

|

Elongation at break % |

720 |

|

Shore hardness A HA |

50-70 |

1. Place a flat glass on a horizontal mold;

2. Lay several layers of EVA film on the flat glass;

3. Place another flat glass;

4. Cover the end surface with the release film, fix the position with the pressure-sensitive tape, and lay the breathable felt at the edges and corners of the flat glass to prevent the vacuum bag from being punctured;

5. Cover the flat glass with a vacuum bag, and seal the vacuum bag with a sealant strip;

6. Install the vacuum valve and connect the vacuum pipe with a quick connector;

7. Vacuuming;

8. Heat to 120-130 ℃ in the oven for heat preservation;

9. Cool down to room temperature and remove the laminated glass from the oven;

10. Remove the release film, breathable felt and vacuum bag;

11. Put the laminated glass into the autoclave, heat and pressurize, and press the laminated glass to the required thickness;