ENsafe™EG interlayer is a high-strength EVA interlayer developed and produced by E&N, and its strength is 2.5 times that of ordinary EVA interlayer. Not only that, ENsafe™EG can be produced by rolling, and it also realizes the continuous processing of EVA laminated glass, which greatly improves the production efficiency.

|

ENsafe™EG:

|

|

|

ENsafe™EG:

|

|

1.The hardness is higher than that of traditional PVB materials.

2.The tensile strength is 2.5 times that of traditional EVA materials.

3.After the glass is broken, it will not fall off or be bent.

4.It has the characteristics of UV filtering, edge stabilization, optical transparency, etc.

5.Flexible processing, available with roll autoclave and vacuum one-step method.

Laminated safety glass has high strength and less deformation under force. Compared with traditional laminated PVB materials, ENsafe™EG has higher hardness, stronger adhesion, lower water absorption and higher melt index. This facilitates the use of thinner, lighter laminated glass that also meets specific loading or structural requirements. Long-term load bending performance is better than PVB material.In addition, ENsafe™EG also has the following advantages:

1.With safety protection performance, it has high safety against hurricane and typhoon.

2.Excellent bearing capacity and rigidity with high strength after crushing, enough residual bearing capacity without falling.

3.To achieve perfect clear glass effect, ENsafe™EG also has excellent transparency, its yellowing index (YID) is <5 at the beginning of use, while the traditional sandwich PVB material is 6-12. Laminated glass with ENsafe™EG provides excellent clarity and reduces unwanted yellowish to greenish casts, consistent with the glass color selected for the project.

4. Durability and quality assurance, providing a more efficient overall architectural design.

5. It is suitable for open side design.

6. Good compatibility with structural adhesives.

7. The method of using the edge frame to block the traditional interlayer PVB material is outdated due to the possibility of edge defects after outdoor use. Compared to many traditional interlayer materials, the polymers used in ENsafe™EG are less susceptible to issues such as moisture or natural aging outdoors, and can help designers achieve open-edge design and application concepts.

8. The installation and interlayer characteristics of the brand PVB interlayer material are also available on E&N ENsafe™EG.

|

Test item |

Test method |

ENsafe™EG |

|

Transmittance |

ISO527-3 |

>90.7% |

|

Haze |

E&N Laboratory |

<0.5% |

|

UV blocked rate |

280-380nm |

>99% |

|

Tensile strength |

ISO527-3 |

>25MPa |

|

Adhesion with glass |

ISO-8510 |

>90N/cm |

|

Elongation at break |

ISO527-3 |

≥800% |

|

Cross-linking rate |

E&N Laboratory |

>85% |

|

Water absorption |

ASTMAD570 |

≤0.1% |

|

High temperature test 4hrs 100℃ |

EN 14449/EN1SO12543 |

No visible change |

|

Humidity resistance Ⅱ 85℃ 85%RH 1000hrs |

ENISO12543 |

Haze appeared just 2.5cm from the edge without bubbles or delamination |

|

UV radiation test UVA340 60℃ 65%RH 2000hrs |

EN14449/EN572 |

Yellowing index:Δ<1 |

|

Pendulum test(hight:1200mm) |

EN14449/EN 12600 |

Qualified |

|

Ball impact peeling resistance(hight:4m) |

GB-15763.3-2009 |

Qualified |

Note:the information and relevant data listed in this article are established in the laboratory of the company's technical department,and their contents are correct based on the truth.However,we will not make any statement or guarantee on the integrity or accuracy of the listed information and data.We provide the content of this article on the condition that it is for the user's reference only,and before using it,decide whether the information and data are suitable for their own purpose of use.In no event shall we be liable or liable for damages of any nature whatsoever arising out of the use of or reliance on the content of this document or the products mentioned herein.

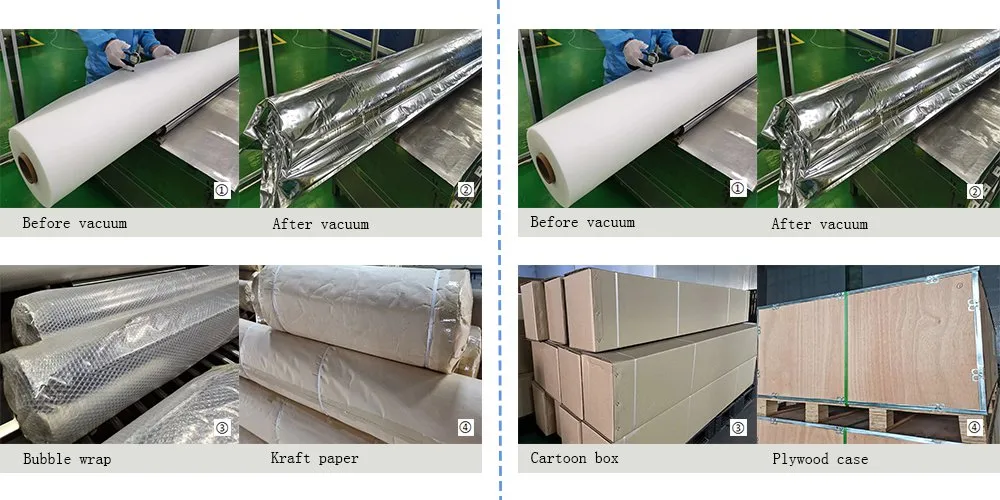

1.Without plywood case: tinfoil vacuum + bubble wrap + composite kraft paper

2.With plywood case: tinfoil vacuum + carton box + plywood case

1 year

|

First Step |

Second Step |

Full Vacuum Retention |

Temperature Out of Furnace |

|

60℃—20mins |

135℃—75mins |

-0.095MPa |

<50℃ |

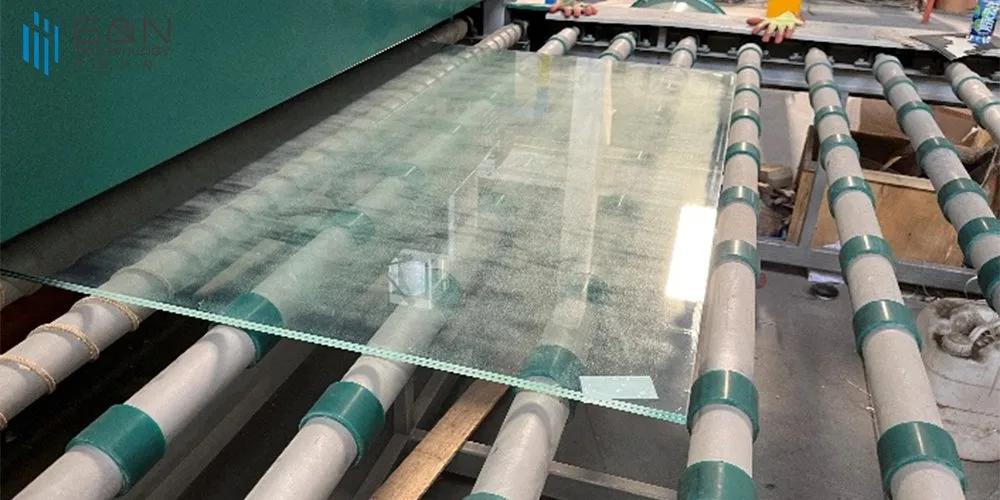

Rolling requirements: After the rolling is completed, the surface temperature of the glass is 66±3℃. Transparent within 2cm of the edge, foggy in the middle of the glass.

|

|

Temperature(℃) |

Time(min) |

Pressure(Mpa) |

|

First Step |

60 |

20 |

0.2 |

|

Second Step |

90 |

30 |

0.3 |

|

Third Step |

130 |

75 |

0.7 |

1.Do you have high strength film?

Yes, we have. The film item EG is one of the highest strength film, its tensile strength value reach 25Mpa with perfect impact resistance, which is able to laminated both in autoclave and laminated oven.

2.How long does the laminated glass with E&N film can be used in outdoor?

Generally it is able to used for outdoor 15 years.

3.Would you have a discount if I have a large order?

Yes, we could offer different discount according to your order quantity.

4.How long is your delivery time?

The general delivery time of LCL is 7-10 days after receiving your order confirmation. Regarding the FCL,it takes 15-20 days.

5.How many rolls can fix in one container?

Our ordinary delivery term is FOB Guangzhou. We also accept EXW, CFR, CIF, DDP, DDU etc. We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.