VE-LYF is a new high-tech product specially developed and produced by our company according to the demand characteristics of decorative glass in the bathroom field. It can not only enhance the safety of bathroom glass, but also have excellent acid-base resistance, which can ensure the stable quality of laminated decorative glass in the environment and extend its service life.

|

VE38LYF:

|

|

|

VE76LYF:

|

|

|

VE-LYF:

|

|

Main Characteristic:

1.Strong acid and alkali resistance

2.High temperature and humidity resistance

3.Low water absorption

4.Excellent boiling resistance

Application:

Bathroom decoration engineering glass

Product Performance Parameter List:

|

Test item |

Test method |

VE-LYF |

|

Transmittance |

ISO527-3 |

>90.5% |

|

Haze |

E&N Laboratory |

<0.5% |

|

UV blocked rate |

280-380nm |

/ |

|

Tensile strength |

ISO527-3 |

>25MPa |

|

Adhesion with glass |

ISO-8510 |

>80N/cm |

|

Elongation at break |

ISO527-3 |

≥800% |

|

Cross-linking rate |

E&N Laboratory |

>85% |

|

Water absorption |

ASTMAD570 |

≤0.1% |

|

High temperature test 8hrs 100℃ |

EN 14449/EN1SO12543 |

No visible change |

|

Acid resistance soak in acid water with pH=5.5~6 for 800 hours at room temperature |

E&N Laboratory |

No visible change |

|

Humidity resistance 85℃ 85%RH 1000hrs |

ENISO12543 |

Haze appeared just 2.5cm from the edge without bubbles or delamination |

|

UV radiation test UVA340 60℃ 65%RH 2000hrs |

EN14449/EN572 |

Yellowing index:Δ<1 |

|

Pendulum test(hight:1200mm) |

EN14449/EN 12600 |

Qualified |

|

Ball impact peeling resistance(hight:4m) |

GB-15763.3-2009 |

Qualified |

Note:the information and relevant data listed in this article are established in the laboratory of the company's technical department,and their contents are correct based on the truth.However,we will not make any statement or guarantee on the integrity or accuracy of the listed information and data.We provide the content of this article on the condition that it is for the user's reference only,and before using it,decide whether the information and data are suitable for their own purpose of use.In no event shall we be liable or liable for damages of any nature whatsoever arising out of the use of or reliance on the content of this document or the products mentioned herein.

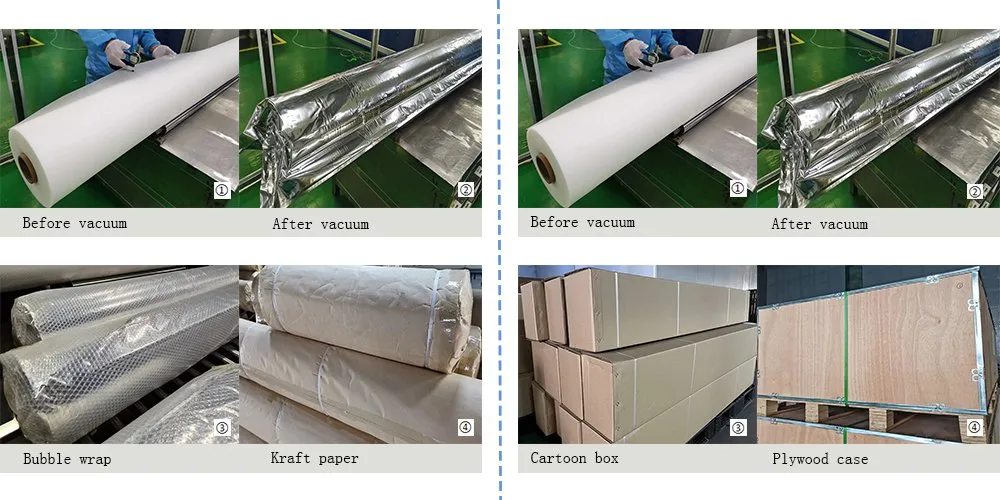

Packing Specification:

1.Without plywood case: tinfoil vacuum + bubble wrap + composite kraft paper

2.With plywood case: tinfoil vacuum + carton box + plywood case

Shelf Life of Product:

1 year

Preparation Before Laminating:

1. Clean and fully dry the glass, there should be no particle dust or oil on the glass surface, EVA film and other intermediate materials are spare.

2. After opening the furnace, cool down for 3~5 minutes, until the vacuum value reaches -0.095MPa, close the furnace door and officially heat.

Parameter setting:

|

First Step |

Second Step |

Full Vacuum Retention |

Temperature Out of Furnace |

|

60℃—10mins |

120℃—60mins |

-0.095MPa |

<50℃ |

The above-mentioned temperature refers to the glass surface temperature.This lamination parameter is suitable for laminated glass with 5mm+0.38EVA+5mm structure.The specific conditions should be adjusted according to the difference of lamination equipment,temperature and humidity,glass thickness,and middle layer material.

1.Can ordinary EVA film be applied to the shower room?

Yes, that's okay, but not as resistant to boiling as its dedicated film.

2.What is the difference between the boiling resistance of VE-LYF and ordinary EVA film?

VE-LYF passed the 8-hour boiling resistance test, while ordinary EVA film can only pass the 2-hour or 4-hour boiling resistance test.

3.Will it degumming over time?

No,it won't.

4.Would you have a discount if I have a large order?

Yes, we could offer different discount according to your order quantity.

5.Is there MOQ?

No,there is not MOQ.But based on FOB term, MOQ is 5000 square meter.