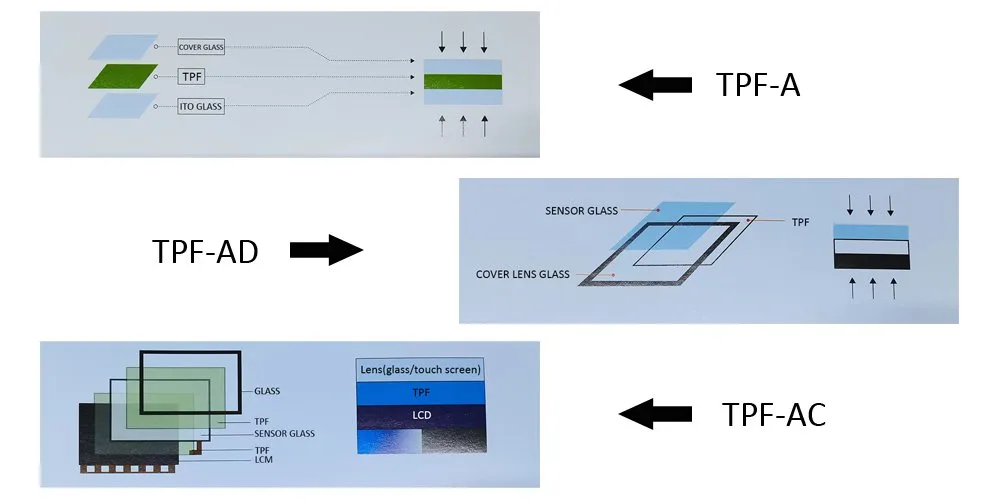

TPF optical adhesive is a UV-curable ionic transparent optical adhesive film.At present, the main models of TPF optical adhesives under E&N are TPF-A, TPF-AD, TPF-AC and so on. They have some subtle differences in some performance.

|

TPF:

|

|

|

TPF:

|

|

|

TPF:

|

|

|

TPF:

|

|

|

TPF:

|

|

|

TPF:

|

|

1. TPF-A is widely used in medium and large size TP lamination with its excellent high yield, high efficiency, high filling, breaking the traditional lamination process, easy to attach, easy to disassemble and so on.

2. TPF-AD has the advantages of excellent high explosion-proof resistance, high bonding strength, high weather resistance, etc. It is widely used in the field of TP display lamination with strict performance requirements.

3. TPF-AC has all the physical and optical properties of TPF optical adhesive series. TPF-AC is widely used in the full fitting of TP+LCM, OGS+LCM, 3D GLASS+LCM and other modules due to its excellent low melting point, high filling and shrinkage.

|

Test item |

TPF-A |

TPF-AD |

TPF-AC |

|

Dielectric constant |

2.99 |

2.99 |

2.99 |

|

Refractive index |

1.49±0.01 at 25℃ |

1.49±0.01 at 25℃ |

1.49±0.01 at 25℃ |

|

Density |

0.95±0.01 |

0.95±0.01 |

0.95±0.01 |

|

Tensile strength |

>10Mpa |

>10Mpa |

>10Mpa |

|

PH value |

7.1 at25℃ |

7.1 at25℃ |

7.1 at25℃ |

|

Curing shrinkage |

≤0.5% |

≤0.5% |

≤0.5% |

|

Melting point |

75±5℃ |

75±5℃ |

55±5℃ |

|

Elongation at break |

>800% |

>800% |

>800% |

|

Bonding strength |

>70N/25mm |

>70N/25mm |

>70N/25mm |

|

Water absorption |

none |

none |

none |

|

Transmittance |

>90% |

>90% |

>90% |

|

Haze |

<0.5% |

<0.5% |

<0.5% |

|

UV curing dose |

2500-4000mJ/cm2 |

2500-4000mJ/cm2 |

2000-4000mJ/cm2 |

|

Cross-linking rate |

>58% |

>58% |

>58% |

|

Boil water for 2hrs |

No bubbles and other defects beyond 13mm beyond the edge or crack |

||

|

High temperature test 85℃ 240/500hrs |

No bubbles and no delamination |

||

|

Low temperature test -40℃ 240/500hrs |

No bubbles and no delamination |

||

|

Humidity resistance 60℃ 90%RH 1000hrs/85℃ 85%RH 1000hrs* |

No bubbles, no delamination and no yellowing |

||

|

Hot and cold shock |

-40℃,85℃ 50/100cycles |

||

|

UV radiation test UVA340 50℃ 60%RH 1000hrs |

No bubbles and no delamination. Yellowing index:Δ≤0.5 |

||

*Humidity resistance 60℃ 90%RH 1000hrs is the experimental condition of TPF-A, 85℃ 85%RH 1000hrs is the experimental condition of TPF-AD and TPF-AC.

E&N's TPF adhesive film composite glass panel always maintains superior light transmittance and clarity in the visible light range of 365-800nm. The refractive index of TPF is about 1.49, which is closer to glass than traditional OCA or LOCA, bringing a more extreme visual display effect.

TPF is not sticky before UV curing, and it can be easily peeled off with only alcohol, leaving no traces on the surface, which greatly reduces production costs and improves yield.

|

|

OCA |

LOCA |

TPF |

|

Craft |

Vacuum heating Pressurized defoaming UV curing |

Adhesive and dispense combination Wipe the spilled glue UV curing |

Vacuum heating Pressurized defoaming UV curing |

|

Product good rate |

Small size high Large size cannot laminate |

Small size high Large size medium |

Small size high Large size high |

|

Operability |

Good |

Inferior |

Excellent |

|

Rework (before curing) |

Good |

Inferior |

Excellent |

|

Ink layer filling |

Less than 10% of OCA thickness |

Excellent |

Excellent |

|

Scope of application |

Soft to hard material bonding Hard to hard material bonding |

Hard to hard material bonding |

Soft to hard material bonding Hard to hard material bonding |

1. The surface of the OCA film is sticky, and it is easy to leave marks on the surface when peeling off the release film, and it is easy to generate air bubbles when laminating. It is easy to absorb dust and impurities and cause secondary pollution.

2. OCA has poor flow performance, and it is difficult to fill the gaps or inks of ITO lines.

3. The bonding performance of OCA is not strong, and there is a risk of rebound in well-fitted products.

4. OCA is not conducive to large-scale lamination, low production efficiency, and high labor cost. When OCA is applied to G + G, it is difficult for medium size (about 10 inches), and it is difficult to perform for large size (such as 15.6 inches, 48 inches, 72 inches), and it becomes more difficult as the size increases. The production efficiency is low and the yield rate is also low. 5.OCA is not easy to rework.

1. When LOCA is cured, it is difficult to cure completely at the frame and FPC, and it needs to be cured again.

2. LOCA glue overflow is difficult to control, and glue overflowing to the edge is difficult to clean up. Especially for large-sized adhesive overflow, it is difficult to control and clean up.

3. The LOCA process is relatively complicated, and it needs to go through the process of dispensing pattern, pre-curing and curing. Products need to be transported to different stations three or four times. The labor cost of production is also higher.

4. LOCA is more likely to produce bubbles. In dispensing, leveling is prone to bubbles.

5. LOCA is not easy to rework.

The TPF developed by E&N overcomes all the disadvantages of the above two processes.

1. The surface of the TPF film is smooth and non-sticky, and the surface has been specially treated without adsorption. The TPF has high cleanliness. It adopts the method of non-attached release film, which has strong repairing ability and is easy to adjust. The film is easy to handle and easy to die cut. Reduced sources of pollution. It ensures the cleanliness and pollution-free of TPF.

2. The surface of TPF is non-sticky, easy to operate during lamination, quick adjustment, and high precision of alignment and lamination.

3. TPF can flow under certain hot pressing conditions, TPF will not produce glue overflow, eliminate the possibility of bubbles, and ensure the yield. Even if bubbles are generated, they can be de-foamed with the help of a defoaming machine, which has no adhesive force in the hot-pressed state, easy to rework, and there is no risk of rebound after UV curing.

4.TPF has no water absorption, and has super anti-water permeability after hot-pressing lamination, Sihao is not subject to external moisture, water vapor erosion and damage, excellent protection of the appearance of the product and the stability of the ITO circuit .

5. The refractive index of TPF light is similar to that of glass, which reduces the refraction of light, restores and enhances the effect of one-piece bonding, and makes the picture more natural and clear.

6.TPF processing technology is simple. The hot-pressing equipment can fit a large number of pieces at one time, with high work efficiency and large production capacity. It can greatly improve production efficiency and reduce production costs.

7. TPF is easy to be reworked, just a few drops of alcohol can be easily peeled off before curing, and reused without leaving traces on the surface of the product.

|

|

Smoothness of film |

Poor film flow properties |

Adaptation size |

Production efficiency and cost |

|

Traditional problem status |

The surface of the solid OCA adhesive is attached with a release film, which is easy to leave marks on the surface of the adhesive tape when peeled off. Because of its sticky surface, it is easy to absorb dust, impurities, and cause secondary pollution. |

Traditional OCA has poor flow performance, and liquid LOCA overflow is difficult to control and clean. It is impossible to fill the ink layer, which is easy to cause weak bonding performance, there is the risk of rebound, and it is not easy to rework. |

The adaptation size is limited, whether it is solid or liquid OCA glue, it is difficult to operate when adapting to the lamination of medium and large sizes, the product good rate is low, and the labor cost is high. |

For the bonding of medium and large size touch panels, the traditional OCA processing technology is complex, the equipment work efficiency is low, the production capacity is small, and the equipment is constrained by the size, etc., resulting in high labor costs, low efficiency, and low product good rate. |

|

TPF solutions |

The surface of TPF optical adhesive is smooth and non-sticky, and the surface has no adsorption force after special treatment, which ensures the cleanliness of TPF and no pollution. |

The TPF optical adhesive is bonded by hot pressing, and finally cured by ultraviolet light. And it can flow in the hot pressing state, and has complete filling ability for the ink layer. No stickiness before UV curing, can be reworked, stable after UV curing, will not rebound due to stress. |

Due to its characteristics, TPF optical adhesive completely solves the defects and bottlenecks of traditional OCA bonding, and the size of TPF bonding is not limited. |

The simple equipment of TPF film processing device adopts one person and one machine. The operability is strong, the equipment can be attached in large quantities at one time, and the work efficiency is high and the production capacity is large. The equipment can adapt to different sizes of lamination, and one piece of equipment can complete lamination of different sizes and quantities, which greatly improves work efficiency and reduces costs. |