Flat-slab glass has the characteristics of super large, super thick and super high. It is generally used in large-scale architectural design. The application cases of cooperation include 4S sales department and glass plank road, so that people can clearly see the appearance of the building, which is beautiful and advanced.

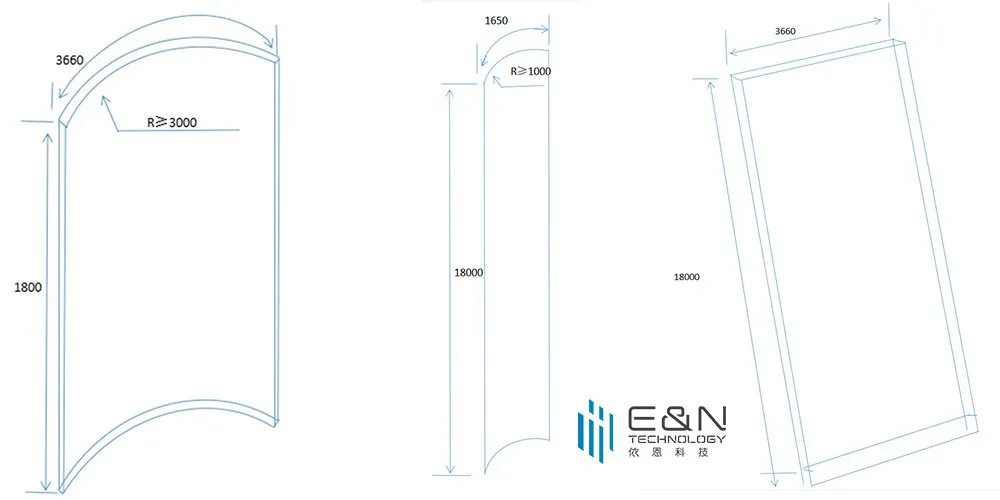

Flat glass Schematic Diagram of Maximum Processing Size:

Max. dimensions of laminated curved tempered glass(left), Max. Bending radius of laminated glass in Jumbo size(middle), Max. Dimensions of laminated glass(right) Unit: (mm)

Plate glass Processing Details:

|

Composite processing technology |

Digital printing glass |

Flat and curved tempered glass |

Laminated glass |

insulating glass |

|

Maximum processing size |

Flat laminated glass: 3660 *20000mm, single curved tempered laminated glass: 3660 * 18000mm |

|||

|

Maximum load |

700KG/m2 |

|||

|

Minimum U valuew/m2·℃ |

0.76 |

|||

|

Advantage |

Applied for indoors and outdoors,have decorative,safety performance and so on. |

Good safety performance, make full use of space,more integrated and aesthetics. |

Good safety performance, with shock resistance,anti theft,bulletproof,explosion-proof,sound proof performance, etc. |

Energy saving and environmental protection materials with good heat insulation,sound insulation,beauty,applicability,and can reduce the deadweight of buildings. |

|

Our advantages |

The two or more pieces glass is bonded together to show a perfect combination of layering. |

|||

Flat glass plate Packing:

First of all, thank you for choosing our company's glass products. For the storage of glass products to be installed, it is recommended that you do the following protection work:

1. The glass must be stacked in a dry room and equipped with rainproof facilities to prevent rainwater from soaking;

2. Avoid storing glass with damp and volatile items (such as acids, alkalis, salts, lime, oils, and alcohol and other chemicals). Note that the glass with the film facing outward should not be used with acids, alkalis, salts, limes, etc. , grease and alcohol and other chemical reagents to wipe the membrane surface;

3. The glass must be kept at an interval and dry to avoid problems such as adsorption, abrasion, edge burst, corner drop or mildew, watermark, rainbow and so on between the glass;

4. The glass should not be moved frequently, and should be properly stored when not in use to avoid unnecessary quality problems;

5. The storage time of glass should not be too long, and it should be used in the order of storage time;

Please be sure to do a good job in the storage of glass products according to the above suggestions, so as to avoid the quality problems of the glass caused by insufficient protection, which will bring you unexpected losses!

The common thickness specification of plate glass is 2mm. 3mm. 4mm. 5mm. 6 mm. 8 mm. 10 mm. 12 mm. 15 mm

19 mm. 22 mm. 25 mm. The thickness shall be indicated in the product qualification certificate. Products other than common thickness specifications shall not be produced. trade

Flat glass is used in other fields besides glass for construction, such as information industry, photovoltaic, vehicles, household appliances, and has special requirements for thickness

The thickness of products other than the common thickness specifications can be produced shall be agreed and specified in the contract and other documents.

A:What is flat glass?

Q:Flat glass, also known as sheet glass or plate glass, is a type of glass that is produced in a flat form. It is commonly used in windows, doors, partitions, and other building applications where transparency and good optical quality are desired. Flat glass can be made using different manufacturing techniques, such as float glass, rolled glass, and drawn glass. These techniques involve melting raw materials such as silica sand, soda ash, and limestone at high temperatures and then cooling the molten glass to form a flat sheet. Flat glass comes in various thicknesses and can be treated with coatings or laminates to enhance its properties, such as energy efficiency, strength, and safety.

A:What are the three major types of flat glass?

Q:Float glass: It is the most common type of flat glass used in architectural and automotive applications. It is made by pouring molten glass onto a bed of molten tin, which causes the glass to spread out and form a uniform sheet. Float glass has excellent optical quality and can be manufactured in different thicknesses.

Rolled glass: This type of flat glass is produced by rolling molten glass between two rollers to form a sheet. Rolled glass is often used for greenhouse glazing, mirrors, and furniture.

Sheet glass: This type of flat glass is made by blowing a cylinder of molten glass, which is then cut open and flattened into a sheet. Sheet glass is typically used for small-scale applications such as picture frames and decorative glass.

A:What type of glass is flat glass?

Q:Flat glass is a type of architectural glass that is used for windows, doors, partitions, and other building applications. It is typically made from soda-lime or silica-based raw materials and is produced in a flat form using various manufacturing techniques such as float glass, rolled glass, and sheet glass. Flat glass is characterized by its uniform thickness, optical clarity, and smooth surfaces, making it ideal for use in architectural settings where transparency and light transmission are important. It can also be treated with coatings and laminates to improve its properties such as energy efficiency, strength, and safety.

A:Why it is called as flat glass?

Q:Flat glass is called "flat" because it is produced in a flat, planar form. Unlike other types of glass, such as curved or bent glass, flat glass does not have any curves or bends in its surface, and it has a consistent thickness throughout its entire surface. This makes it suitable for use in applications such as windows and mirrors, where a smooth, uniform surface is desired. The term "flat glass" is often used interchangeably with "sheet glass" or "plate glass," which also refer to glass that is manufactured in a flat format.

A:Is plate glass flat?

Q:Yes, plate glass is a type of flat glass that is made by pouring molten glass onto a metal table and then rolling it out to form a sheet. Plate glass also goes through an annealing process to remove internal stresses and improve its strength. The resulting glass is uniform in thickness and has smooth, flat surfaces on both sides. Plate glass is commonly used in applications such as windows, doors, mirrors, and tabletops. However, the term "plate glass" is not commonly used today, and it has been largely replaced by the more generic term "flat glass."