Hyperbolic glass, the special glass meets the special design requirements and meets the designer's artistic idea. It is safe and stable while bending on both sides, ensuring the beauty and safety of the building. The application case of cooperation is Chongqing Fuling Meteorological Station.

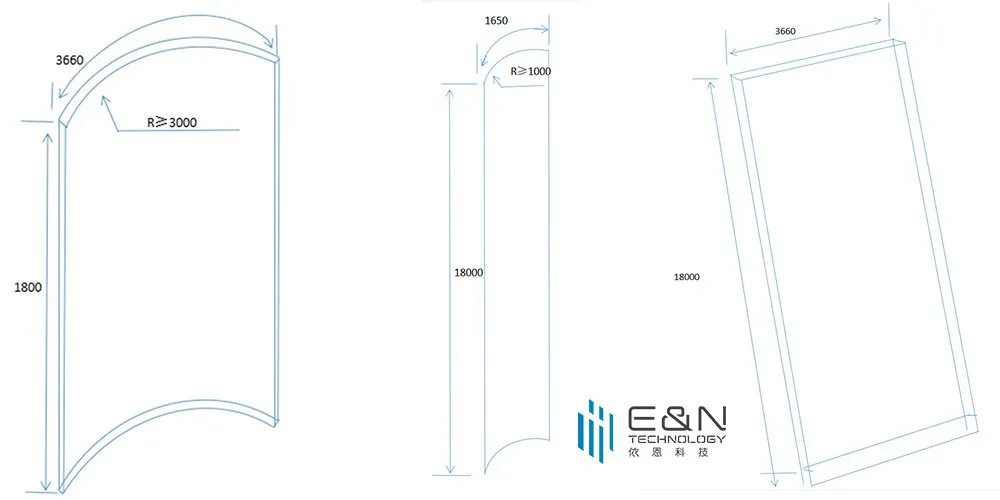

Schematic Diagram of Maximum Processing Size:

Max. dimensions of laminated curved tempered glass(left), Max. Bending radius of laminated glass in Jumbo size(middle), Max. Dimensions of laminated glass(right) Unit: (mm)

Processing Details:

|

Composite processing technology |

Digital printing glass |

Flat and curved tempered glass |

Laminated glass |

insulating glass |

|

Maximum processing size |

Flat laminated glass: 3660 *20000mm, single curved tempered laminated glass: 3660 * 18000mm |

|||

|

Maximum load |

700KG/m2 |

|||

|

Minimum U valuew/m2·℃ |

0.76 |

|||

|

Advantage |

Applied for indoors and outdoors,have decorative,safety performance and so on. |

Good safety performance, make full use of space,more integrated and aesthetics. |

Good safety performance, with shock resistance,anti theft,bulletproof,explosion-proof,sound proof performance, etc. |

Energy saving and environmental protection materials with good heat insulation,sound insulation,beauty,applicability,and can reduce the deadweight of buildings. |

|

Our advantages |

The two or more pieces glass is bonded together to show a perfect combination of layering. |

|||

Packing:

From the appearance alone, the new generation weather radar in Fuling feels full of features. In addition, it can obtain more accurate data, monitor short-term heavy rainfall and extreme disaster weather in real-time, and help meteorological personnel make early warnings, thereby reducing losses caused by extreme weather.

First of all, thank you for choosing our company's glass products. For the storage of glass products to be installed, it is recommended that you do the following protection work:

1. The glass must be stacked in a dry room and equipped with rainproof facilities to prevent rainwater from soaking;

2. Avoid storing glass with damp and volatile items (such as acids, alkalis, salts, lime, oils, and alcohol and other chemicals). Note that the glass with the film facing outward should not be used with acids, alkalis, salts, limes, etc. , grease and alcohol and other chemical reagents to wipe the membrane surface;

3. The glass must be kept at an interval and dry to avoid problems such as adsorption, abrasion, edge burst, corner drop or mildew, watermark, rainbow and so on between the glass;

4. The glass should not be moved frequently, and should be properly stored when not in use to avoid unnecessary quality problems;

5. The storage time of glass should not be too long, and it should be used in the order of storage time;

Please be sure to do a good job in the storage of glass products according to the above suggestions, so as to avoid the quality problems of the glass caused by insufficient protection, which will bring you unexpected losses!

A:What is hyperbolic glass

Q:Hyperbolic Glass is a type of curved glass that has been shaped using a process called hyperbolic paraboloid bending. This technique involves heating the glass sheet until it becomes pliable, then shaping it into a double-curved surface using a mold. The resulting shape resembles a saddle, with two opposing curves that create a unique aesthetic effect.

Hyperbolic Glass is often used in modern architecture to create curved facades or windows that allow natural light to penetrate deep into buildings while also providing energy efficiency and acoustic insulation. Its unique shape and optical properties make it a popular choice for creating visually striking designs that stand out from traditional flat glass applications.

A:What is hyperbolic glass

Q:Hyperboloid glass, also known as hyperbolic paraboloid glass or hypar glass, is a type of curved glass that has several unique characteristics. Some of the key characteristics of hyperboloid glass include:

Curved shape: Hyperboloid glass has a distinct curved shape that is created by intersecting two hyperbolic paraboloids.

Structural strength: The curved shape of hyperboloid glass provides it with excellent structural strength, making it ideal for use in architectural applications such as roofs and facades.

Light filtration: Depending on the thickness and tint of the glass, hyperboloid glass can filter out varying amounts of sunlight, providing both shade and natural light to interior spaces.

Aesthetics: The unique curved shape of hyperboloid glass can create interesting visual effects and add a distinctive architectural element to buildings.

Complexity: Due to its complex shape, designing and manufacturing hyperboloid glass can be challenging and require specialized expertise.

Overall, hyperboloid glass is a versatile and visually striking material that offers a range of benefits for architectural design.

A:What is hyperboloid glass processing technology

Q:The processing technology for hyperboloid glass is complex and requires specialized expertise. The following are the general steps involved in manufacturing hyperboloid glass:

Design: The first step in manufacturing hyperboloid glass is to design the shape of the glass according to the specific architectural requirements.

Pattern making: A pattern of the hyperboloid shape is created using wood or metal, which serves as a template for shaping the glass.

Glass cutting: Sheets of glass are cut according to the pattern using a diamond-tipped cutting tool or a waterjet cutter.

Glass bending: The curved shape of the hyperboloid glass is achieved by heating the glass sheets to a temperature at which they become soft and pliable, and then placing them onto a mold that has been shaped to the desired curve. The glass is then allowed to cool slowly, which sets it into the new shape.

Finishing: After the glass has been shaped, it may be further processed to refine its finish, such as polishing or sandblasting.

Quality control: Finally, the hyperboloid glass is inspected for any defects or imperfections before it is installed in the building.

It's worth noting that this is a simplified overview of the process, and the exact steps and techniques used may vary depending on the manufacturer and specific requirements of each project.