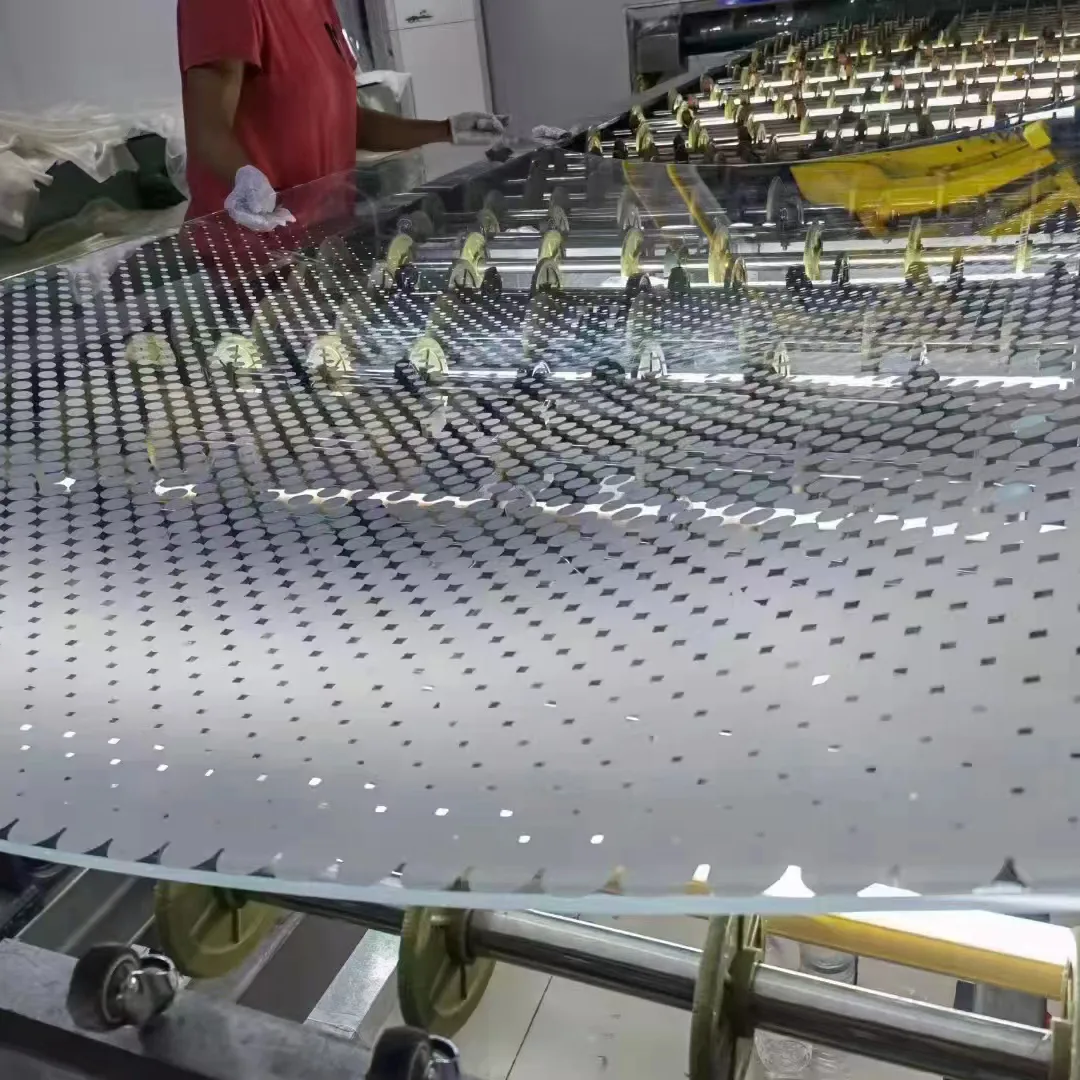

Printed glass is to print inorganic glaze on the glass surface, then dry, temper or heat treatment, and permanently sinter the glaze on the glass surface to obtain a wear-resistant, acid and alkali resistant decorative glass product.

1. Various colors and patterns, wide selection. In the curtain wall combination, it can contrast other glass or carry out color matching.

2. Printed glass can be installed on the support structure.

3. Non-absorbent, non-permeable and easy to clean.

4. The color glaze is an inorganic color glaze of the same glass material, which does not fade or peel off, so the original color tone is consistent with the life of the building.

5. Composite processing such as coating, interlayer and hollowing can be carried out to obtain special properties for other purposes.

6. After tempering treatment, it has higher impact resistance, thermal shock resistance and higher safety performance.

7. Custom printed glass is available, and special glass patterns can be customized according to customer needs

1. Building decoration industry

2. Furniture glass

3. Electronic glass

Glass selection and cutting → stacking according to specifications → wiping and scraping putty before installation → inlaying glass → scraping putty and cleaning edges, etc.

Glass selection and cutting: cut the glass to be installed according to the specification and quantity of the part, and stack the cut glass according to the specification.

Scraping the bottom putty: before the glass is installed, clean the cut. First, evenly apply 1~3mm bottom putty between the bottom surface of the glass and the cut along the full length of the cut, then push the glass flat, compact, and then collect the bottom putty.