Our entire process of glass lamination equipment is film washing, lamination, furnace inlet, furnace outlet, and cleaning. The specific operations are as follows:

1. The water used for cleaning glass should be pure water or deionized water (we can use a regular cleaning machine).

2. After cleaning the glass, use dry purified hot air to blow dry, and there should be no dirt, water marks, or watermarks left on the surface (this operation is automatically completed in the cleaning machine).

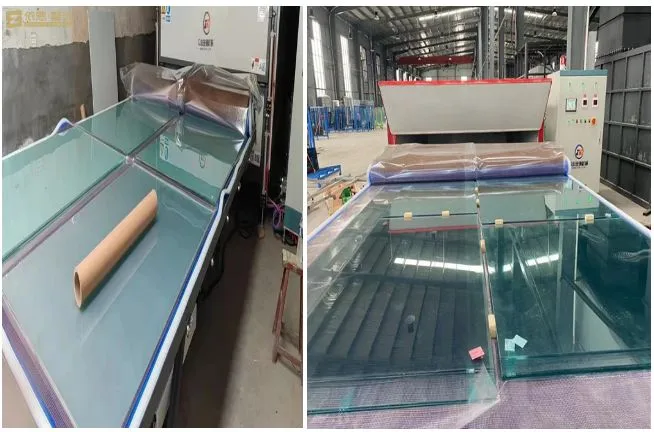

3. When laminating, lay the film flat on the bottom glass, gently brush off the wrinkles on the film with your hand, and then close the upper glass and align it all around. In principle, there should be a dedicated lamination room for lamination, but in reality, we have

A single integrated console is sufficient. The console is designed according to your glass specifications.

4. It is critical to reasonably grasp the temperature and time for the molding of EVA Laminated glass. In general, vacuum forming is completed in five stages, namely: cold vacuuming - temperature rise hot vacuuming - insulation and vacuum preservation-

Stop pumping after cooling down - discharge from the furnace. This stage usually only takes 50-75min, saving time and electricity. The entire operation is completed by the PLC control system, which is very convenient to operate

5. After being fired, just put the glass on the shelf to cool it down

If you have any further questions, we will communicate again! We also welcome you to visit and inspect our company.